The Fischcon Onshore Firewater Solution delivers a dependable firewater supply for locations where access to open water is limited—whether due to restricted space, challenging soil conditions or physical barriers such as roads and pipelines. This solution drastically reduces the need for civil works.

Many terminals and industrial sites face limited or difficult access to open water. Space for standard vertical pumps is often unavailable, and soil conditions or contamination can complicate civil works.

In these situations, installing a firewater system traditionally requires extensive civil interventions, such as reinforcing a jetty, constructing a new pump house or removing contaminated soil. These measures increase cost and may introduce delays, complex permitting processes and operational disruptions.

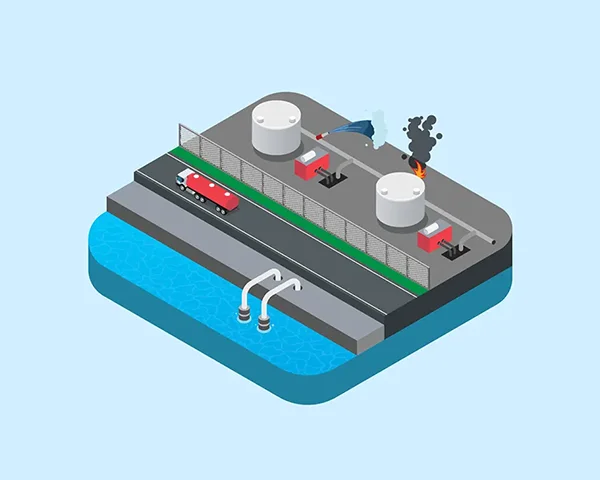

The Fischcon Onshore Firewater Solution eliminates the need for heavy civil works. Our configuration places the pump and the drive unit separately—positioned up to 130 metres apart. The pump is installed at the water intake, while the drive unit is placed in an accessible area with sufficient space.

This flexible, Plug & Play system adapts seamlessly to your site conditions. When an area is classified as gas-hazardous, the drive unit is simply positioned outside the hazardous zone.

Fischcon supplies a diesel-hydraulic firewater system with a fully submerged, hydraulically driven pump installed below the waterline—such as on a quay or jetty. Because the hydraulic drive separates the pump from the engine, installation requires minimal civil modifications and allows for precise placement.

The pumps discharge directly into the plant’s main firewater ring, removing the need for water storage. Individual units deliver between 400 and 1200 m³/h. Hydraulic Power Units (HPUs) are available in containerised or skid-mounted versions, depending on site requirements.

For Plug & Play installations, each HPU/pump system is housed in a protective container or enclosure. These can be equipped with dust filters, fire suppression systems and a range of corrosion-resistant coatings to suit the environment. From hydraulic lines to hang-off frames, every component is engineered for long-term performance in demanding onshore conditions.

Two hydraulically driven submerged pumps of 800 m³/h integrated into a fully autonomous system. Flexible installation on an existing quay eliminated the need for heavy civil work.

Challenging access to water due to a main road. Solution with three lift pumps and a containerised pump house, delivering 1035 m³/h at 12.5 bar. Installed without affecting existing infrastructure.

Firewater system with long distance between water source and installation. Diesel-hydraulic submerged pumps deliver 1200 m³/h at 16.7 bar. Achieved without major civil interventions.

Each firewater pump system is housed in protective containers or enclosures, with optional dust filtration and corrosion-resistant coatings. Every component, from hydraulic piping to hang-off frames, is engineered for long-term performance and durability in harsh Onshore environments.

Ready to learn more about our High Capacity Firewater Systems? Contact us today to speak with one of our knowledgeable representatives and discover how Fischcon can fulfill your industrial fire suppression needs.

Terms and Conditions Privacy statement Cookies Follow us on: