Designing, assembling, and maintaining firewater pump packages is complex work. At Fischcon, we understand that. That’s why we walk alongside you—from the first sketches to long-term operation.

Every project starts with listening. What’s the challenge? What are the constraints? Our engineers translate these questions into practical, economical, and long-lasting solutions.

We use advanced 3D tools to design integrated systems made from high-quality, pre-manufactured components—customised to your application. All work follows strict QA/QC protocols and safety standards. And before anything leaves our site, it’s thoroughly tested—together with you and a certifying authority—so there are no surprises later on.

In our 4,400 m² facility, we assemble complete systems by integrating all components—mechanical, electrical, and control—onto a single skid. This includes welding, pipe fitting, panel installation, and painting, all carried out in-house.

By delivering fully assembled and tested skid packages, we reduce the complexity and time needed for on-site installation—ensuring a smooth and efficient handover.

Testing isn’t an afterthought—it’s built into everything we do. At our facility, we perform full hydrotests, run tests, and functional checks on all integrated systems. With our own power supply, we can test motors up to 650 kW. For larger capacities, we provide flexible test solutions.

You’re invited to be part of this process. We carry out all tests in close cooperation with your team, third-party inspectors, and certifying bodies—so you know exactly what you’re getting.

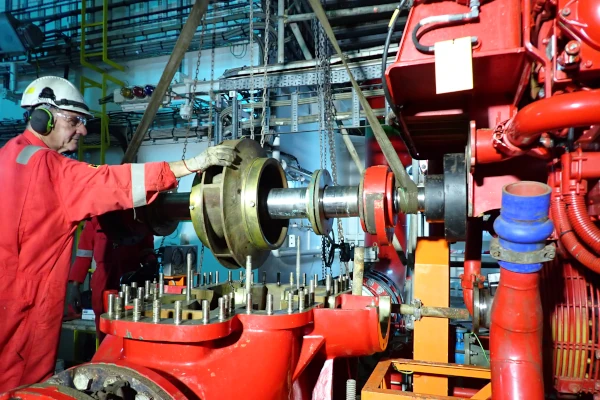

Our skilled technicians handle the installation process, ensuring your equipment is set up correctly and safely.

Even after delivery, you’re not on your own. After the packages are successfully tested and accepted, we are available for installation and after-sales service. Our qualified team of field service technicians, will install and commission the equipment to ensure proper functionality and operation.

Our skilled technicians handle the installation process, ensuring your equipment is set up correctly and safely.

To keep your operations running seamlessly, we offer maintenance service contracts. These contracts ensure your equipment remains in optimal condition, minimizing any potential downtime.

Need a replacement part fast? Located in Vianen, our warehouse plans, organizes, and stores your OEM spares. We guarantee availability and reduced lead times, so you get the parts you need, when you need them.

Our experienced field service technicians are ready to perform maintenance and repairs at your location—whether Onshore, Offshore, or at our fully-equipped service workshop in Vianen.

Training for operational and supervisory personnel can be provided at our factory, as well as at Onshore and Offshore locations worldwide.

Terms and Conditions Privacy statement Cookies Follow us on: